All aluminum grades or alloys can be mel-ted using one of our round top furnaces. This furnace is a modified model suitable for laboratories and workshops.

Induction Heating Coils Design And Basic Pdf Induction Heating Heating Coil Induction

A gas-fired crucible furnace is designed and fabricated for melting scrap aluminium.

. The pulse jet type dust collector is an improved high-efficient model dust collector. A furnace helps to solve this problem distributing the heat evenly. Round top charge melting furnaces receive a charge from charging buckets and melt it.

The molten aluminium is then poured into mold of required shape and size. 2 IMI-NFG Course on Processing of Glass - Lecture 3. Glass melting furnaces Furnace design focus on continuous melting tanks Process steps Furnace operation 2.

The design of an aluminium melting furnace has faced two challenges. You cant beat a furnace measured efficiencies as high as 0175 kwhrlb of. Open-hearth furnaces to converters and electric furnaces for steel production are in use today worldwide.

The DOE study also reported that there is little poten-. Melting aluminum furnace flue gas circulation to save fuel heat balance calculation 1. This furnace is designed and fabricated using locally available materials and butane gas as the thermal energy source in heating up the system to the melting point of aluminium 6604 C.

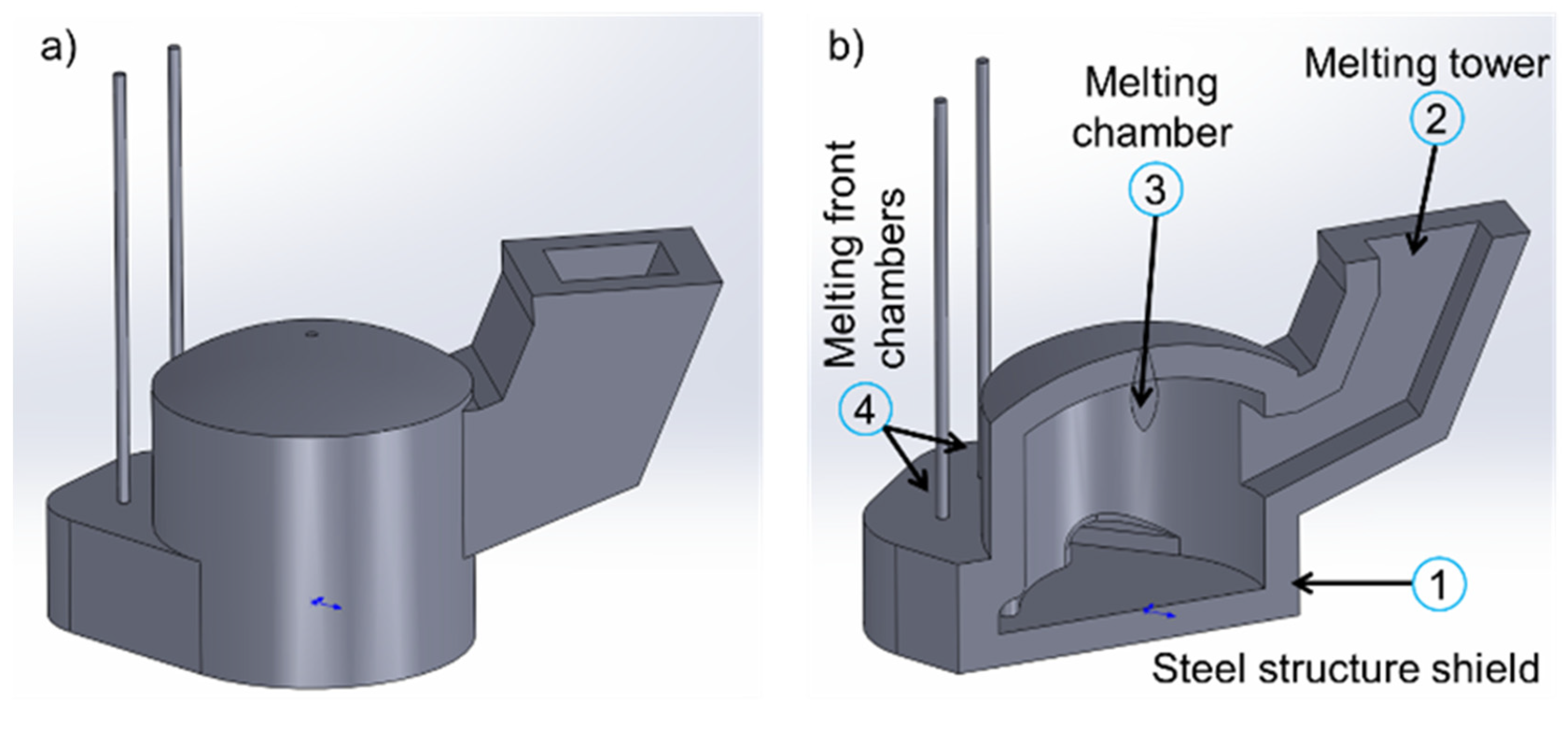

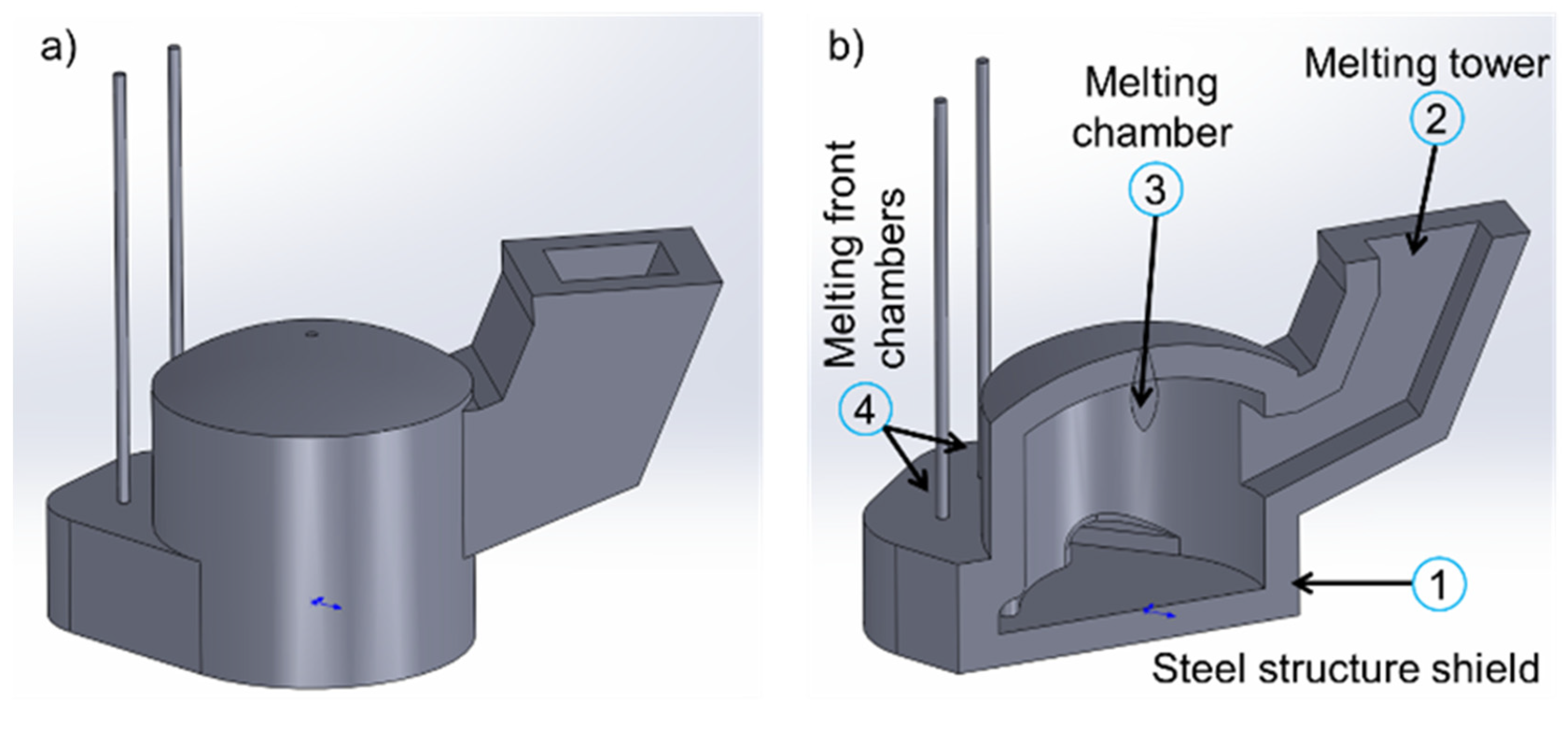

Basics of industrial glass melting furnaces mathieuhubertcelsiannl 4 Outline of this lecture 1. Aluminum casting foundries have a long history of gas-fired furnaces. ModernDesign Features- Micro Jet Melter.

Capacity - up to 1100 pounds per hour High Energy Efficiency - Close to 1000 btus per pound of aluminum High Metal Quality Molten Aluminum has lower gas and inclusion levels Low Melt Loss - aluminum is lost to dross Compact Design and Footprint Low Temperature Variations - 10F. The molten aluminium is casted to a desired shape and size either as ingot or end product. About Design Furnace Aluminium Pdf Melting.

CS0103 Low NOx radiant tube burner for Aluminum aging furnace. As ingot or end product. These furnaces are tapped to transport the molten metal to holding furnaces.

Here in Nigeria Ajaokuta Steel Company and Delta Steel Company are examples of steel making companies that use these types of furnaces. ANDRITZ Bricmont has completed instal-. About Pdf Design Melting Furnace Aluminium.

A typical installation has one holder for each melter. Aluminium Melting Furnace Design Pdf. Type and design of the holding furnaces vary in conformity with different operating requirements.

This paper first uses fluid dynamics to model the aluminium. For laboratories and workshops. Melting units so as to have pourable metal available in the holding furnaces at any time.

This furnace is designed and fabricated using locally available materials and butane gas as the thermal energy source in heating up the system to the melting point of aluminium 6604oC. IMI-NFG Course on Processing of Glass - Lecture 3. The developed Aluminum melting furnace will not only melt Aluminium but also a metal that have a melting temperature below 700 0C.

Use of LPG will reduce the emission of greenhouse gases GHGs. It is a durable refractory lined furnace that eliminates the use of crucibles. ACKNOWLEDGEMENTS We would like to take this opportunity to express my honor respect deep gratitude and genuine regard to Dr.

The molten aluminium is casted to a desired shape and size either. 5 iron 22 chrome and 5. Aluminium melting furnace design pdf Written By quianarom23033 Sunday May 8 2022 Add Comment Edit.

Electrically heated hearth-type furnace capacity. The experimental reverberatory furnace ERF is a one ton nominal capacity research furnace capable of melting 1000 lbs per hour with its twin 08 MMBtuhr burners. The dispersed flame contains the same amount of energy but with a much more effective distribution.

The study reported that typical metal melting furnaces range in thermal efficiency from 7 percent to 76 percent and they range in melt loss from 075 percent to 6 percent. This paper proposes the design of a coreless induction furnace to melt Aluminum which is represented by a transformer with N primary turns and one short circuited secondary turn. The furnace is manufactured using locally available materials and LPG Liquefied Petroleum Gas as thermal energy source to heat up the crucible upto melting point of aluminium.

On the furnace design the fuel used and the method of imparting heat to the metals. Following the rapid melting of feed material at the lower area the outlet flow of the waste gas pre-heat cold material in the overlying shaft area. Point of aluminium 6604oC.

Aluminum being the most abundant metallic element forming about 8 of the. This furnace is designed and fabricated using locally available. The countercurrent flow of molten material and gas permits a very effective use of waste heat recovery down to 300 C according to the principle.

Modelling and simulative optimization. The DOE study also reported that there is little poten-. Melting in the melting shaft.

Capacity lb kg power rating power input vac 3 phase 6050 hz. Materials and butane gas as the thermal energy source in heating up the system to the melting. 17th IEEE International Multi Topic Conference 2014.

Remelting works prefer either resistance-heated hearth-type furnaces or induction-heated mixers. Introduction Melting aluminium furnace is the main equipment in the process of smelting aluminum it is used to melt aluminum to make its quality uniform and meet the requirement of the chemical composition which is in order to cast and provide.

Oil Fired Furnace And Induction Furnace A Review Semantic Scholar

Metals Free Full Text Mathematical Modelling For Furnace Design Refining Molten Aluminum Html

Pdf Design Of A Coreless Induction Furnace For Melting Iron Semantic Scholar

Induction Crucible Furnace 4 Download Scientific Diagram

Tower Melting Furnaces Wide Variety Of High Quality Furnaces Products From World S Largest Manufacturer And Supplie Heating Element Furnace Industrial Heating

Pdf Design Of Aluminium Melting Furnace Using Coconut Shell Charcoal On Laboratory Scale As Learning Medium

Schematic Of Induction Furnace Download Scientific Diagram

Pdf Design Of A Coreless Induction Furnace For Melting Iron Semantic Scholar

0 comments

Post a Comment